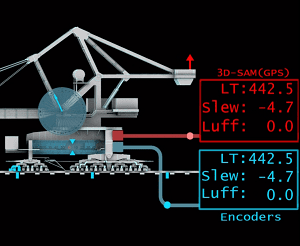

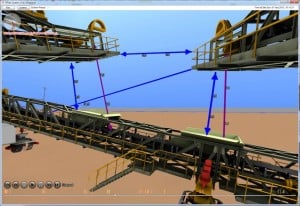

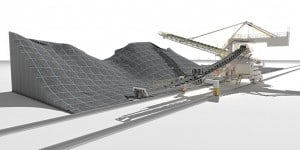

Today 3D-SAM is working at a number different locations within the Australian mining industry. Although these Gen2 technology versions are currently hosted exclusively on industrial Linux computers, the company is actively working on porting these successful designs across to more powerful Gen3.0 FPGA versions which will deliver huge increases in both processing speed and support much larger 3D environment sizes. Gen 3.0 versions are anticipated Q2 2018.